The two-seat SubSonex JSX-2T project was announced just before AirVenture 2019 receiving a very positive reception during the show, and in the months since. Many prospective customers have expressed interest in the new jet, and a number of eager customers have added their names to our first several JSX-2T production slots via our refundable* JSX-2T Kit Reservation Deposits.

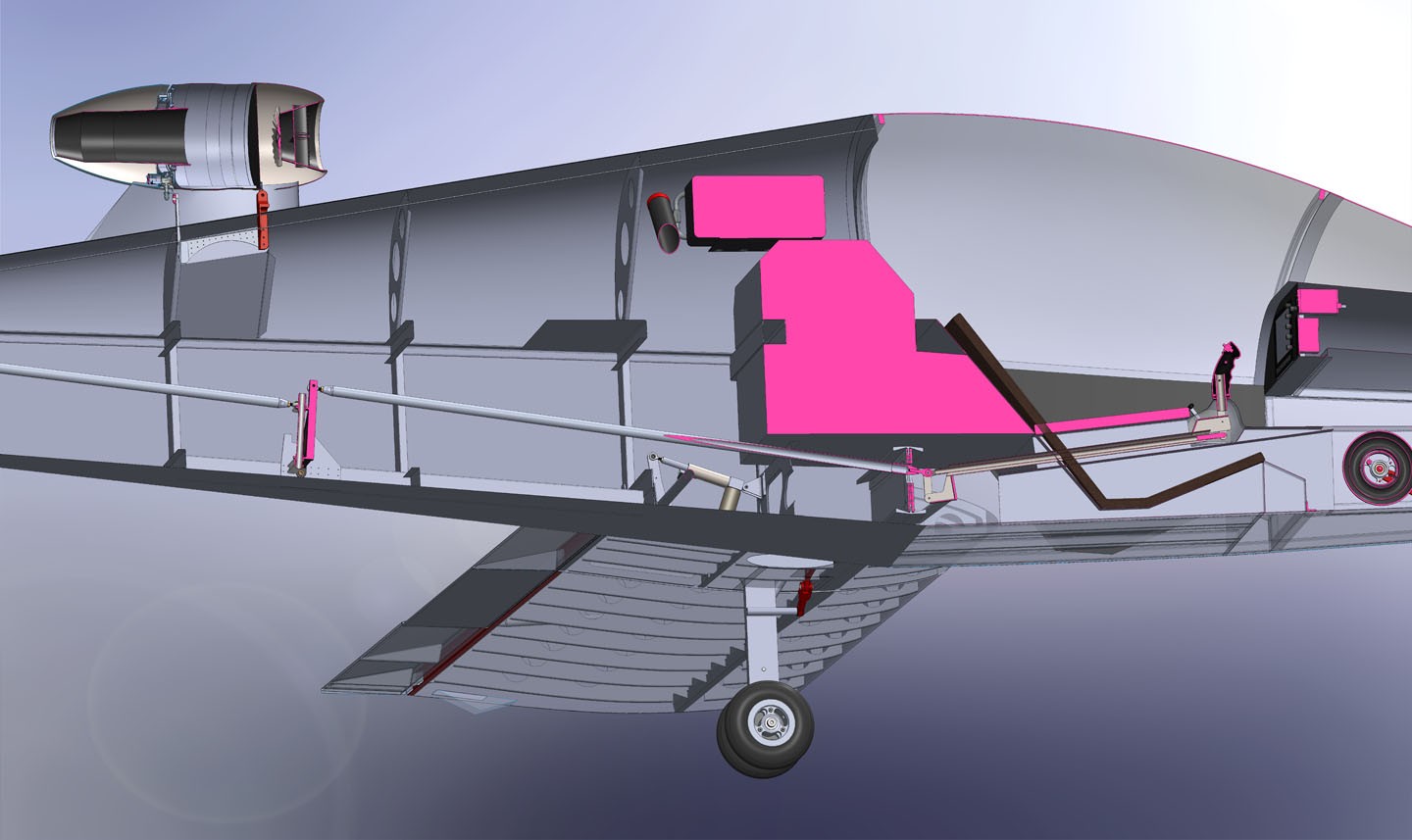

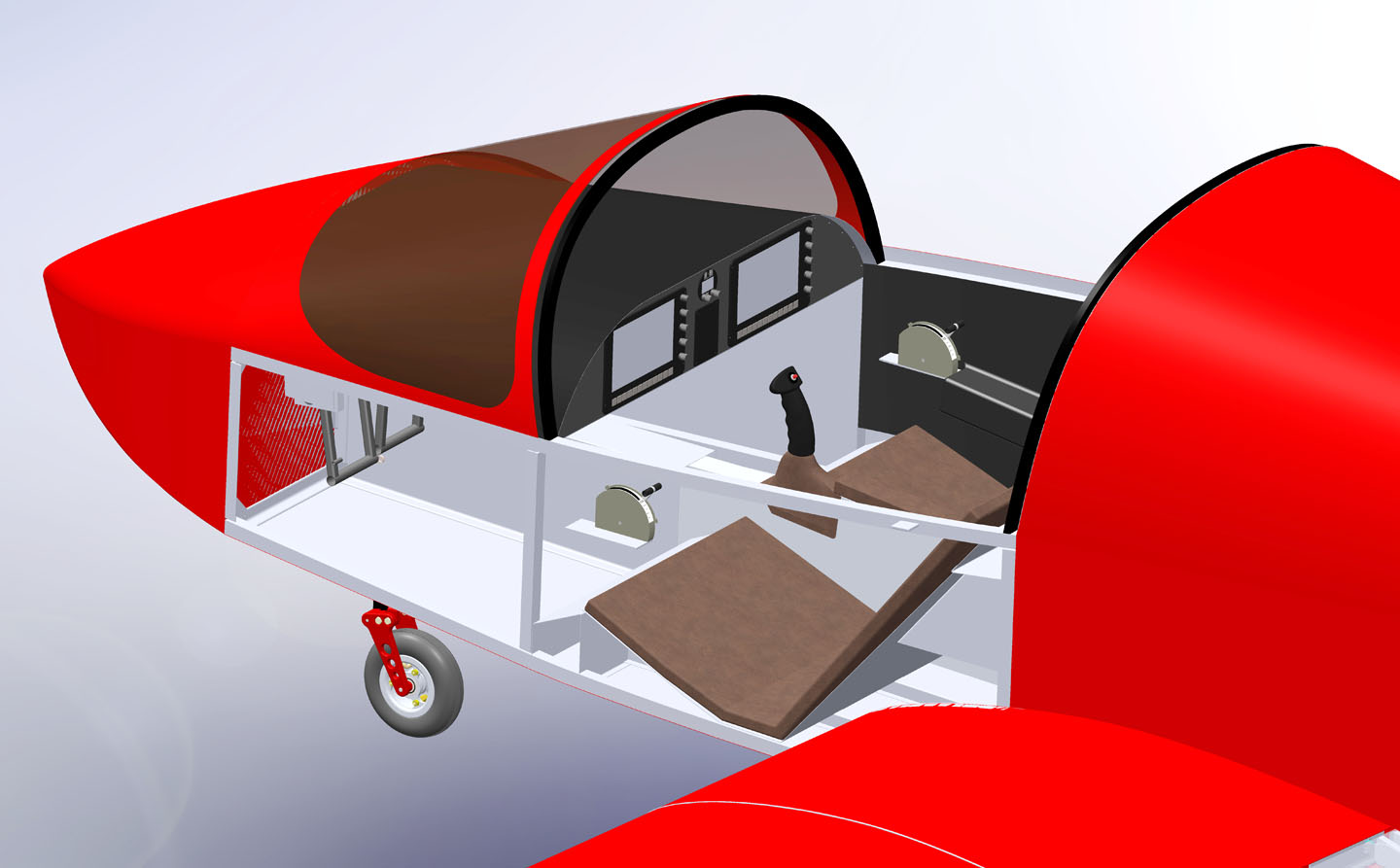

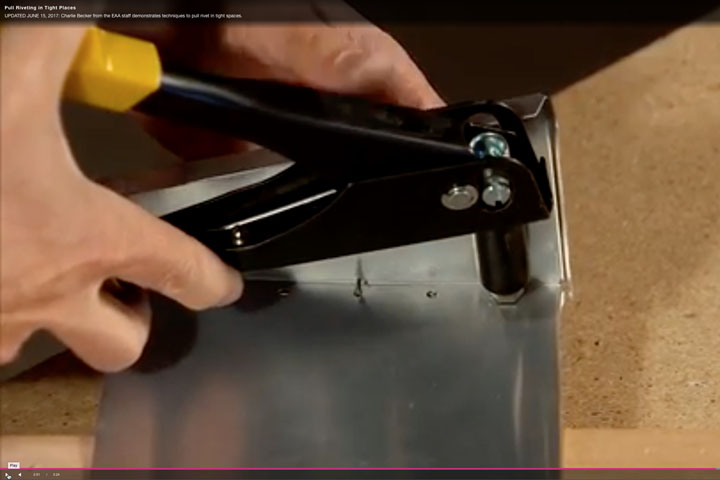

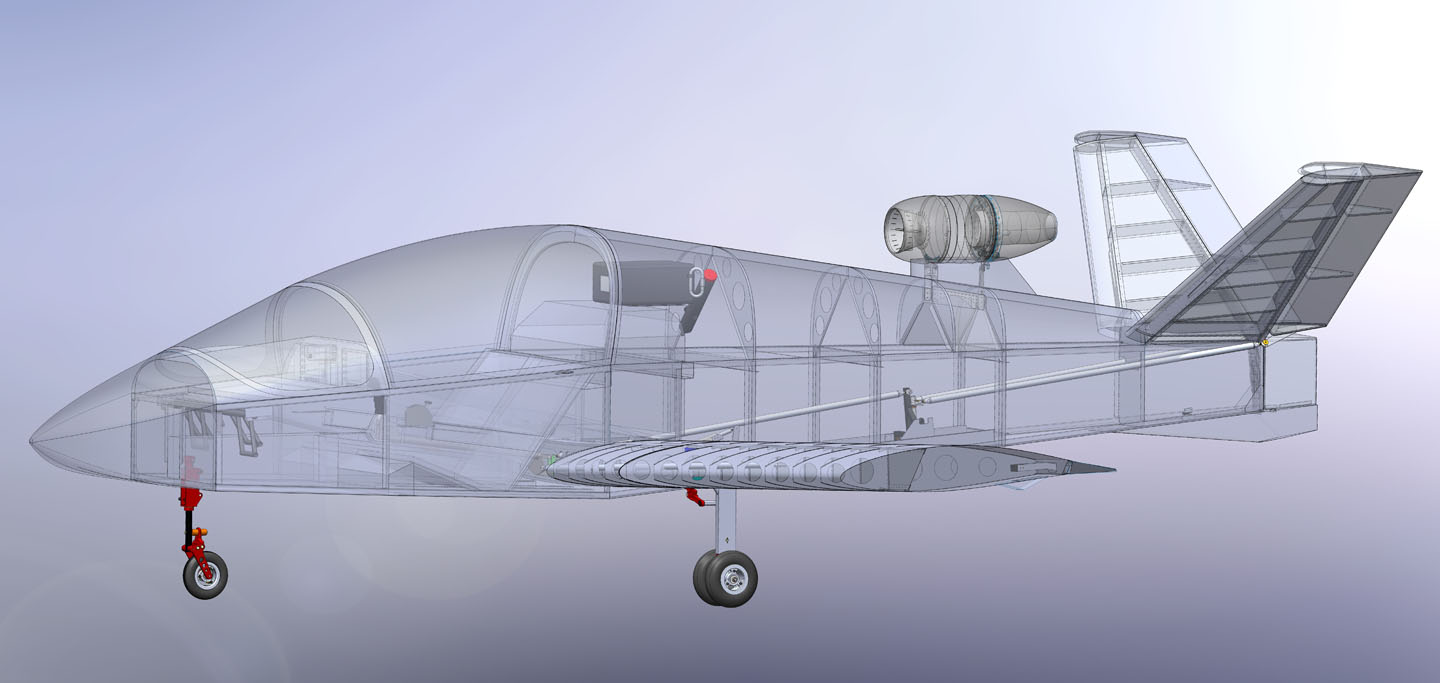

Development work has continued on JSX-2T since AirVenture and much progress has been made. Most of the work to-date has been in the form of engineering analysis and detailed modeling of the aircraft in SolidWorks 3D CAD software. Building on the extensive 3D modeling design process of the Sonex, Waiex and Xenos B-Models, SubSonex JSX-2T will be the most extensively modeled design in the Sonex Aircraft product line thus-far, which will help speed the prototype construction process, as-well as the process of transitioning to kit production.

|

|

Next Steps:

With most of the design work completed in SolidWorks, along with most of the engineering and analysis work for the aircraft, construction of physical prototype aircraft parts for JSX-2T will begin later this Winter with the goal of having a prototype aircraft completed and flying this Summer. We will have a prototype on-display in our booth at EAA AirVenture Oshkosh 2020, and at our Open House event before the show.

Once the majority of critical flight testing tasks are completed, Sonex Aircraft will offer deposit holders the opportunity to turn their deposits into firm orders. We plan to begin the process of kitting the aircraft this Fall to begin shipping the first kits around year-end, 2020.

Progress To-Date:

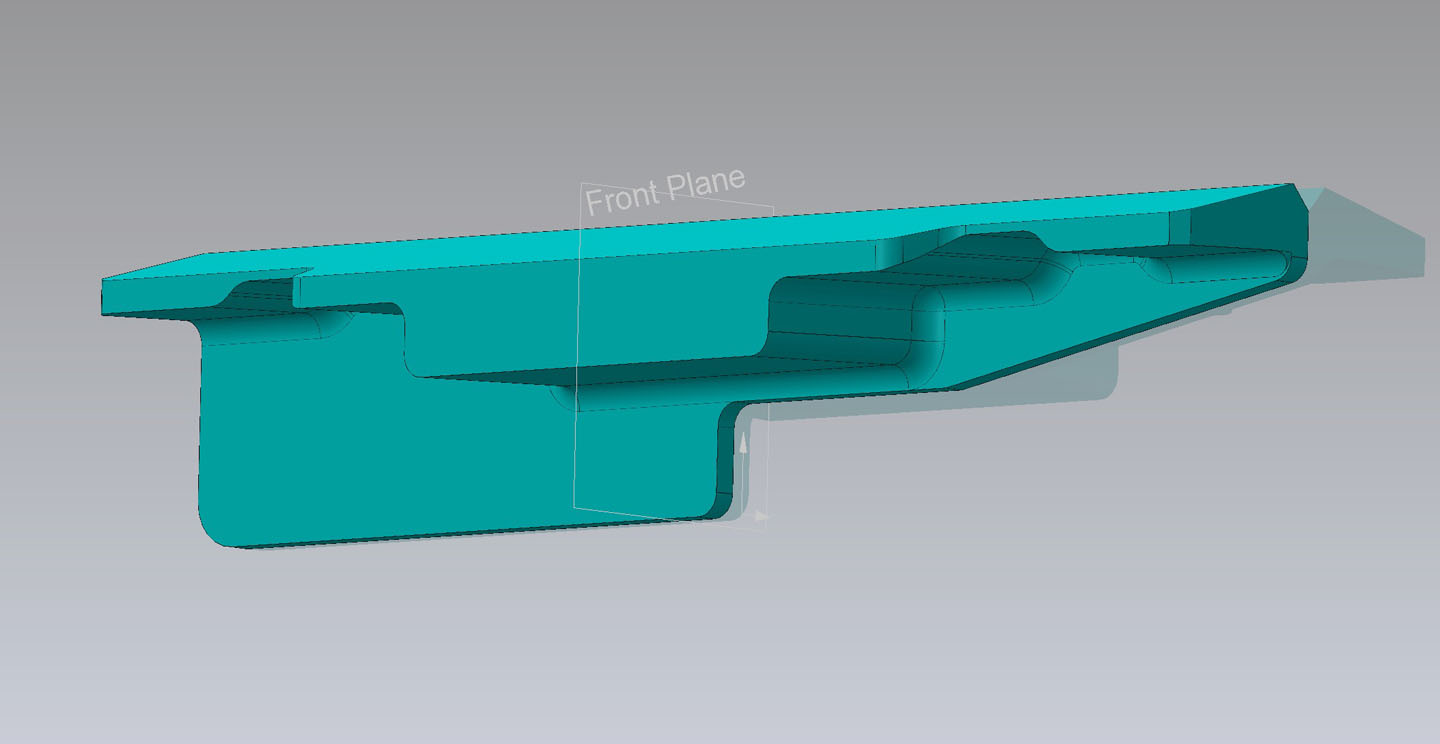

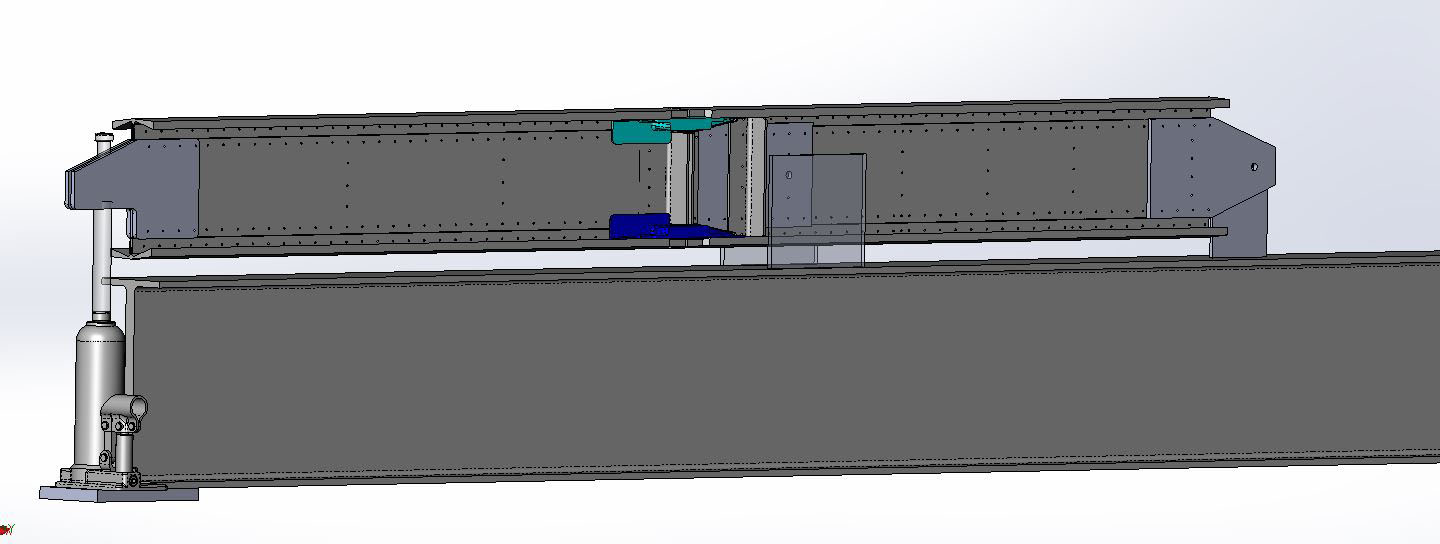

SubSonex JSX-2T Solid Model Rendering

SubSonex JSX-2T Solid Model Rendering

Tail Structure:

The JSX-2T tail surfaces have been reviewed to verify proper tail sizing for the desired moments and to verify the proper Y-Tail geometry. Structural design of the tail’s internal components has been completed, along with the tail’s structural integration with the aft fuselage.

Since the announcement of JSX-2T, some customers have asked about ordering a tail kit. We will not be offering JSX-2T tail kits until flight test of the aircraft has been conducted. Some customers have asked if any of our existing tail kits are used on JSX-2T. No, JSX-2T utilizes different tail specific to the design’s needs.

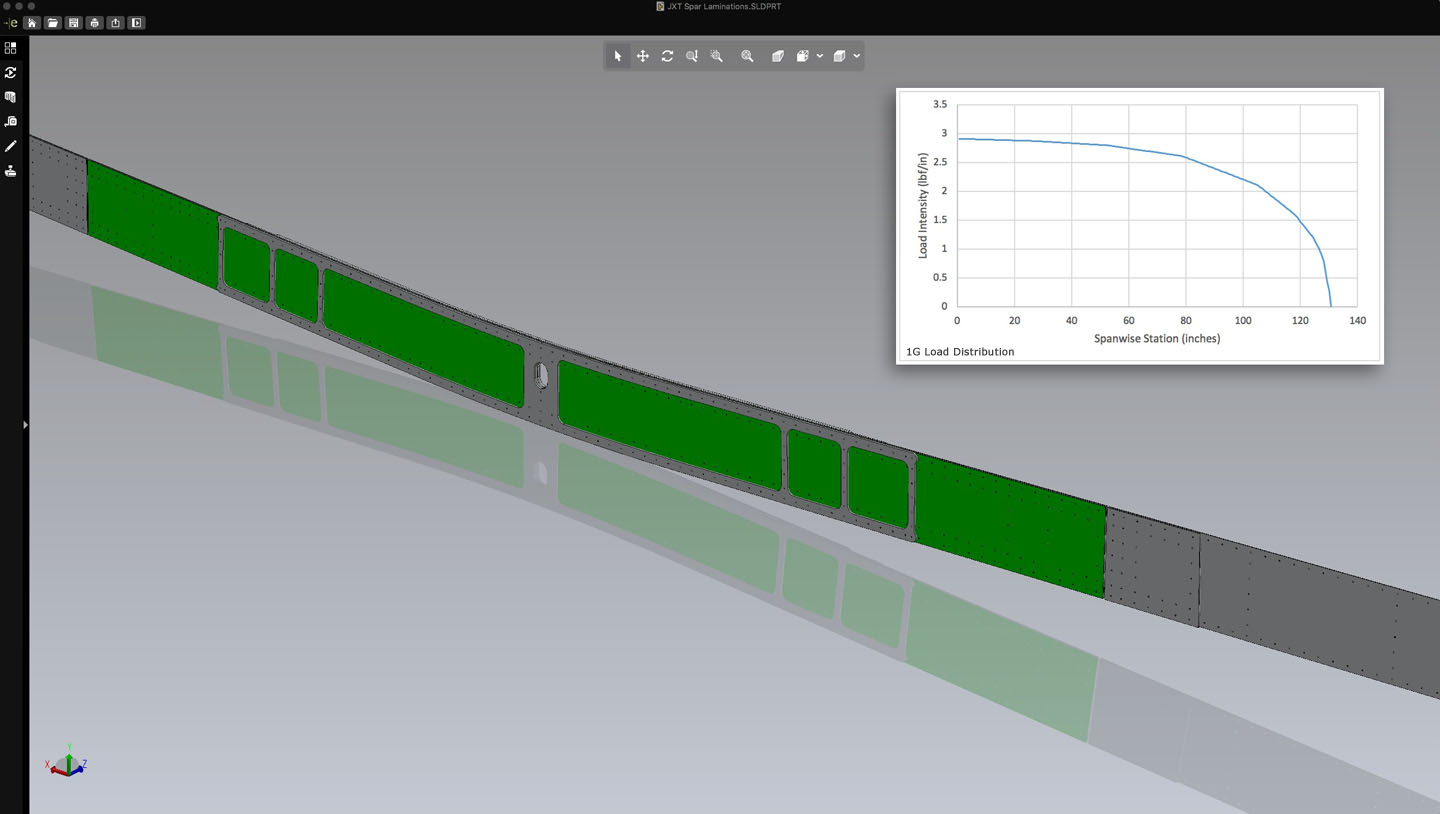

Wing Structure:

Considerable time is dedicated to design and analysis of the wing structure of any new aircraft. Like the single-place SubSonex JSX-2, JSX-2T has two major design considerations that require special emphasis: The joint between inboard and removable outboard wing panels, and the design and integration of the retractable main landing gear components.

Like JSX-2, JSX-2T will utilize machined wing attach ties, however, the higher gross weight of the aircraft requires four ties per wing instead of two, and the ties have to be redesigned and resized for the specific loading and strain properties of the JSX-2T wing spar. Each tie will have three bolts per-side vs. four bolts in JSX-2. This will minimize the increase in the number of bolts that need to be removed in order to remove the wing panel to 12 bolts per wing instead of 16. Design of the ties is complete and a first article set is currently being produced for testing. The wing joint/ties will be tested independently of the rest of the structure before a complete wing sample is constructed and tested.

The test rig will utilize two sample main wing spar sections joined by the test article wing ties. A bending load will be applied to the test assembly to match the shear and moment at the design limit load of the aircraft, at design ultimate load, and will be further increased until failure of the assembly is achieved.

Design of the greater Main Wing Spar assembly is complete, allowing design of the remainder of the wing, which is also nearly complete. This includes arrangement of the main landing gear components and the adjacent wing components. Shortly after successful completion of wing tie testing, construction will begin on the full JSX-2T load test wing, and planning is already underway to design the full-scale wing test apparatus and load cases.

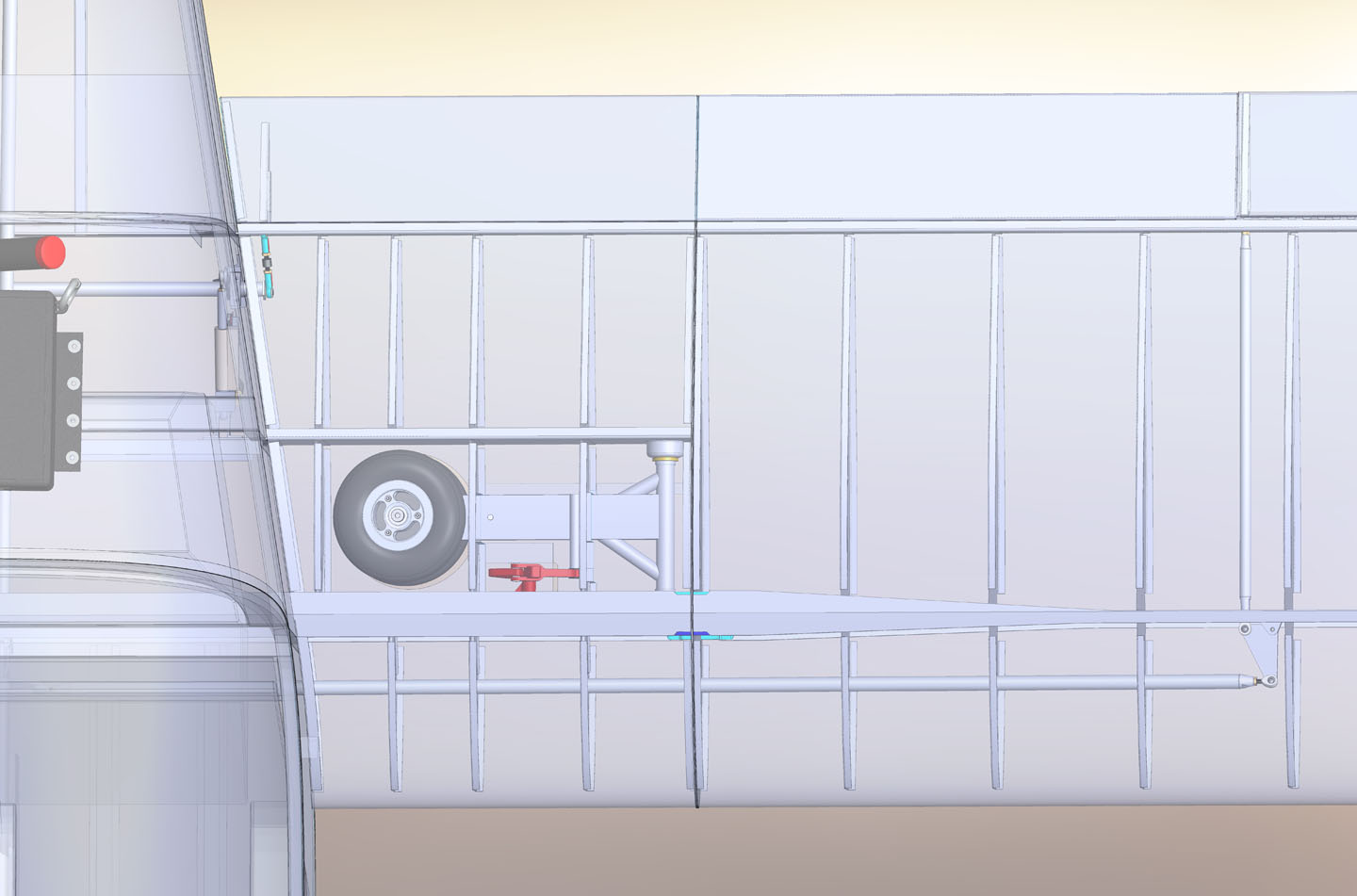

Landing Gear System:

The retractable gear system for JSX-2T will be different than that used in the single-place jet. Instead of using pneumatic cylinders, Sonex Aircraft is planning a single actuator design with mechanical linkage to each gear leg. The actuator will be an electric/hydraulic unit, which uses an electric motor to pressurize a self-encapsulated hydraulic system powering a mechanical actuator. This system retains the powerful, non-compressible benefits hydraulics with none of the plumbing work and potential leakage hassles. Additionally, this is the simplest way to utilize hydraulics in an aircraft that cannot provide engine-driven hydraulic power.

Use of a single actuator is planned to reduce the weight, cost and electrical demands of the system vs. utilizing three actuators. Gear linkages will retain the current over-center down-lock geometries of the current single-place jet. Due to the fact that the gear will be held in the up position by a non-compressible hydraulic unit, gear up-locks will not be necessary to prevent gear from sneaking out of the wheel wells under G-loads. Further, the linked system eliminates the possibility of a hazardous asymmetrical gear deployment. Manual disconnection from the cockpit of a single linkage to the electric/hydraulic actuator will allow the gear to deploy via gravity in the event of a system failure.

Due to the larger size and increased max. gross weight of the JSX-2T, the diameter of the wheels will be enlarged, which allows larger, more powerful brakes to be used. The system will use a scaled-up version of the main gear trucks/brake units currently featured in SubSonex JSX-2. The gear legs are also lengthened to give the aircraft more ground clearance — an aesthetic consideration making the aircraft look “right” in its scaled-up form that will also prevent the jet’s larger wing area from increasing float in ground-effect.

Control System:

Like the Sonex, Waiex and Xenos B-Models, SubSonex JSX-2T will utilize a single center-mounted control stick to minimize weight and maximize useful load and performance. Routing and geometry of all control system components have been designed, and structural requirements for the control system components are being analyzed.

Fuel System:

Work continues to optimize the JSX-2T fuel system. The aircraft will have approximately 10 additional gallons of useable fuel capacity vs. the single-place jet, offering a moderate increase in range and endurance while still keeping the aircraft within its intended max. gross weight and an acceptable CG range. The increase in fuel capacity will also be vital if a more powerful engine with higher fuel burn were to be utilized in the future. Design considerations including mounting provisions, filler neck and sump locations and CG migration all have to be accounted for as we finalize the fuel cell’s geometry. Like the single-place JSX-2, the JSX-2T fuel cell will be removable for maintenance access to other components in the fuselage.

Fuselage and Cockpit:

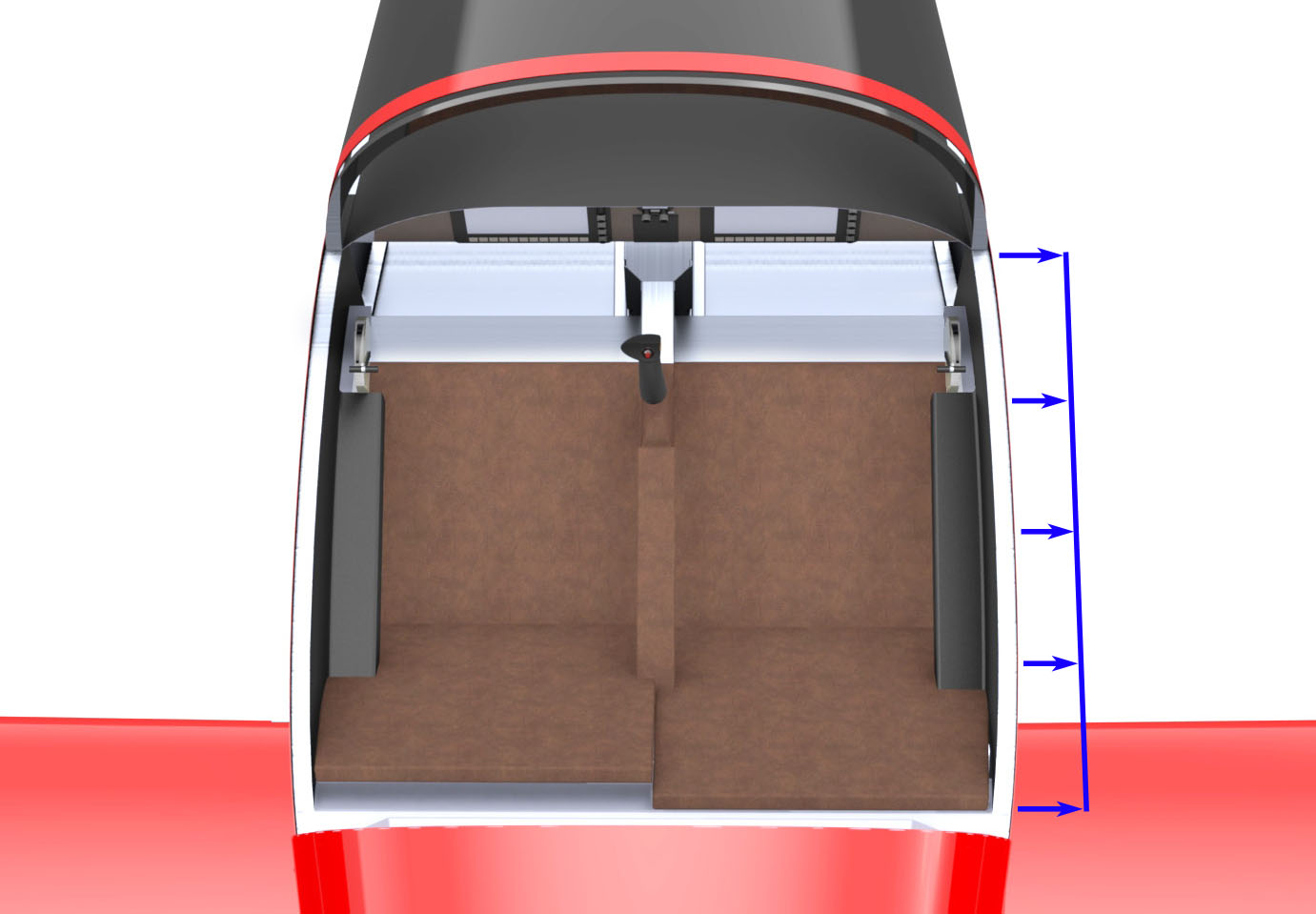

Design of the fuselage is driven primarily by the design and interface of other major aircraft components including the wing, tail, fuel system, engine mounting etc. The cockpit has the largest impact upon the design of the fuselage and much work has been focused on the cockpit design of JSX-2T to accommodate two occupants comfortably, including tall pilots, with access for both pilots to controls including dual throttles. Several features of the JSX-2T cockpit have been designed to make this possible:

- Curved Fuselage Sides: The forward fuselage/cockpit side walls of JSX-2T will be curved. Like “bubble doors” on a high-wing aircraft, these curved cockpit side walls give pilots more room at the shoulders, elbows and hips. This amounts to a 2″ total increase in cockpit width in these areas vs. our earlier aircraft designs with straight longerons and fuselage side walls.

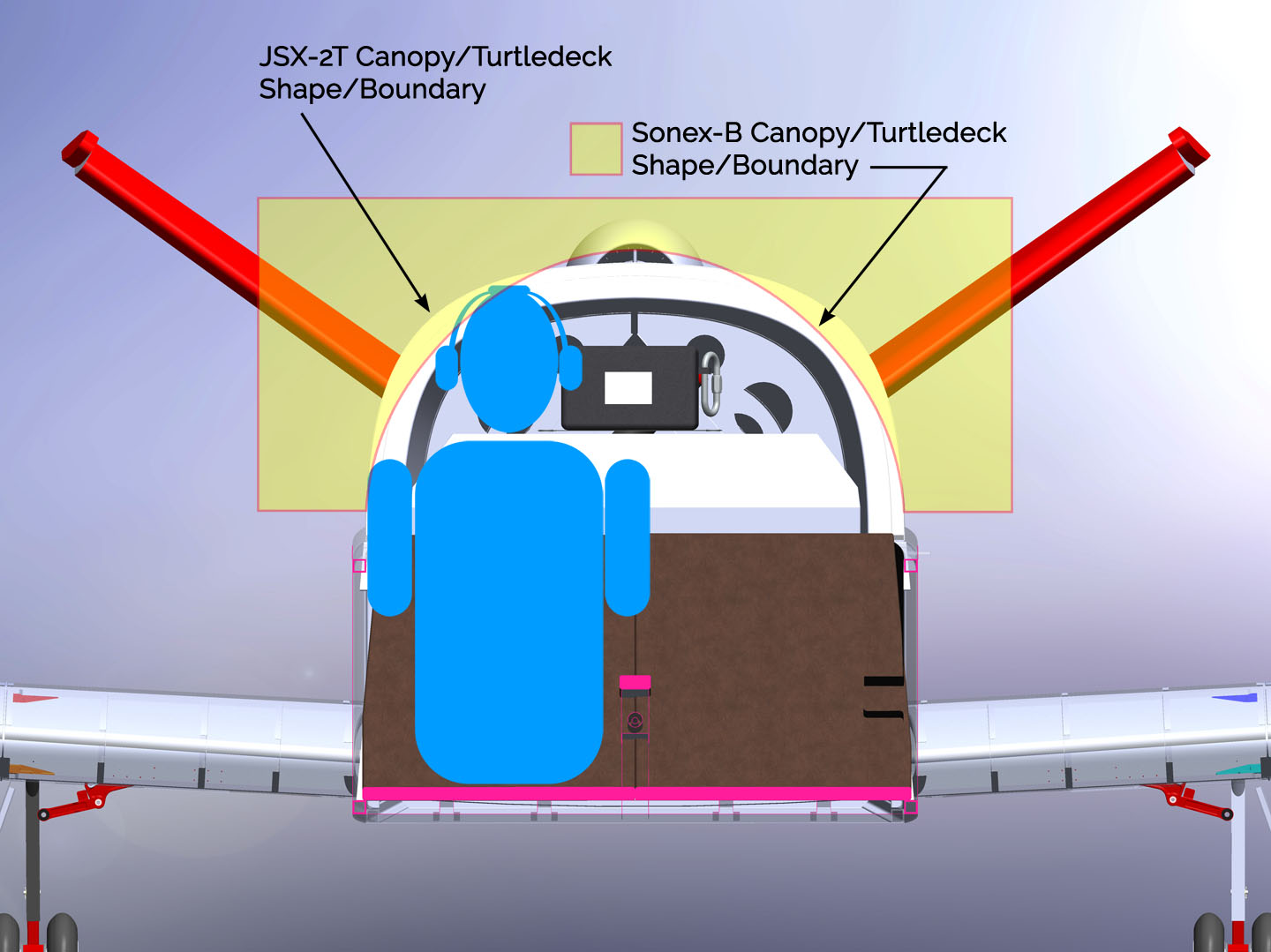

- New Canopy and Turtledeck Shape: The traditional arc of typical Sonex Aircraft turtledeck formers and canopies has been changed for JSX-2T, reducing the total height of the apex of that arc while making the arc taller at either side of the aircraft centerline. This gives pilots an increase in head room while minimizing the total height of the fuselage.

- Adjustable Seat Backs: The seat backs in JSX-2T will have approximately 3″ of independent adjustment, allowing each pilot to vary the distance of head and shoulders from the instrument panel and controls while finding the most comfortable seat back angle. This also allows occupants to stagger the seat backs from one another to optimize space available for shoulder width.

- Ample Leg Room: Like the single-place SubSonex and the Onex, JSX-2T does not have the constraints of an angled firewall or forward bulkhead for landing gear mount provisions. This gives the cockpit ample leg room and the ability to vary the distance of the rudder pedals from the seat.

In modeling the cockpit with SolidWorks, we are able to fit a 95th percentile 6′ 3″ tall person of even proportions into the aircraft. Fit will vary from one individual to the next, however, as ratio of inseam vs. torso length varies, along with weight, and each individual’s perception of a comfortable fit in an aircraft. Like any aircraft, you’ll have to try it on for size, however, pilots of more average height and weight can count on being able to fit in the JSX-2T comfortably.

SubSonex Transition Training:

SubSonex JSX-2T is designed not only as a light jet aircraft that you can share with others, but also as a trainer. Sonex Aircraft and Desert Aerospace plan to convert the current BonusJet training program for the SubSonex into a program giving dual instruction in the JSX-2T, benefiting pilots of both single- and two-place SubSonex models as-well as owners of other microjet aircraft types with an apples-to-apples training experience.

A Note About the PBS TJ-150:

Our original announcement of the JSX-2T’s development included information about PBS’s new TJ-150 turbojet engine as a potential powerplant for the two-place SubSonex. This has attracted much interest and attention and has been the focus of many questions since AirVenture. Please note that Sonex Aircraft does not see the TJ-150 as a viable option for our aircraft yet. The TJ-150 is a very new engine design with almost no fleet history worldwide and inspection intervals for the engine are only 50 hours. With time, more testing and fleet history those intervals may increase incrementally as they did for the TJ-100 years ago. Also like the TJ-100, we are hoping that PBS eventually offers a de-rated version of the TJ-150 allowing for inspection intervals similar to the 300 hour intervals specified for the current PBS TJ-100 E3S variant that we currently use.

Other important considerations with regard to the PBS TJ-150 are price and fuel burn. The TJ-150 is currently priced over $80,000 which may cause the aircraft to exceed the available budget of many customers. Fuel burn of the TJ-150 is approximately 30% higher than that of the PBS TJ-100 E3S, which will significantly limit endurance and range.

The SubSonex JSX-2T is being designed for use with the current PBS TJ-100 E3S engine. While the aircraft has a higher gross weight than the single-place jet, they both have similar wing loading and the new aircraft will fly quite well with its increased wing span and chord. Cruise speeds and top speeds of the JSX-2T will be lower than JSX-2, approximately 210+ mph in cruise vs. 230+ mph cruise in the single-place, which is the trade-off that customers will have to accept in-order to add that extra seat.

Thank You, and Stay Tuned!

Sonex Aircraft would like to extend a huge Thank You to those customers who have expressed their high-level of interest in SubSonex JSX-2T and their confidence in our design team by placing a Kit Reservation Deposit! If you are interested in joining them by putting your name on a production JSX-2T kit, more information can be found below. If you have any level of interest in this new aircraft, we encourage you to sign-up for our SubSonex Mailing List via the form at the top of this page. This mailing list will automatically notify you via email of future updates about the two-place SubSonex JSX-2T.

Update 08/23/2021:

We’re working hard to get prototype parts made! As-soon as we have some metal in the shop to show, we’ll publish our next update. Look for the new jet at EAA AirVenture Oshkosh 2022 and we hope to be shipping kits by the end of 2022!

*Specifications SubSonext to Change Without Notice |

||||||||||||||||||||||||||||||||||||