Tail Kit Production Starting

Sonex is pleased to report that a successful static load test of the Sonex Highwing horizontal tail section was conducted last week! With the completion of this milestone and positive results from our flight testing with full-span wing tips (see below), production of Tail Kit parts is ready to commence. If you don’t already have your Sonex Highwing Tail Kit order in-place, order today! Tail Kit shipping sequence will be in-accordance with already established Sonex Highwing Kit Reservation Deposit position numbers and estimated ship dates will be given to customers by mid-November.

Highwing Tail Load Testing

Consistent with all Sonex aircraft tail structures, the Highwing tail performed well in-excess of the required loading and was tested to 150% of ultimate load (225% of design limit load) with no failure (breakage) or yielding (permanent deformation) of the structure or sample fuselage section. This feature of Sonex designs not only ensure structural capability of the tail in all flight regimes, but also eliminates concerns with moving the aircraft around by the tail in your hangar.

Full Span Wing Tips

Following our October 8th Webinar Update, the temporary metal set of full span wing tips for the Sonex Highwing have been completed and test flown as molds for the composite wing tips are being made. Flights with the full span tips have completed our validation of rudder handling and authority demonstrating good directional stability and rudder authority allowing a crosswind component of 18 knots during one recent landing. There will be more full span tests to follow including Vx and Vy testing, more stall testing, and more cruise configuration testing, but all preliminary results have been very positive.

Our First Outside Review of the Sonex Highwing

On Friday, we also invited Casey to fly the Highwing with Sonex test pilot Joe Norris to give us his feedback. Casey’s feedback was quite positive and informative as an outside source with extensive experience regularly flying his Sonex along with a multitude of other homebuilt and Light Sport aircraft for his family’s maintenance and training operation. See his thoughts on the Highwing in his Instagram post on this page.

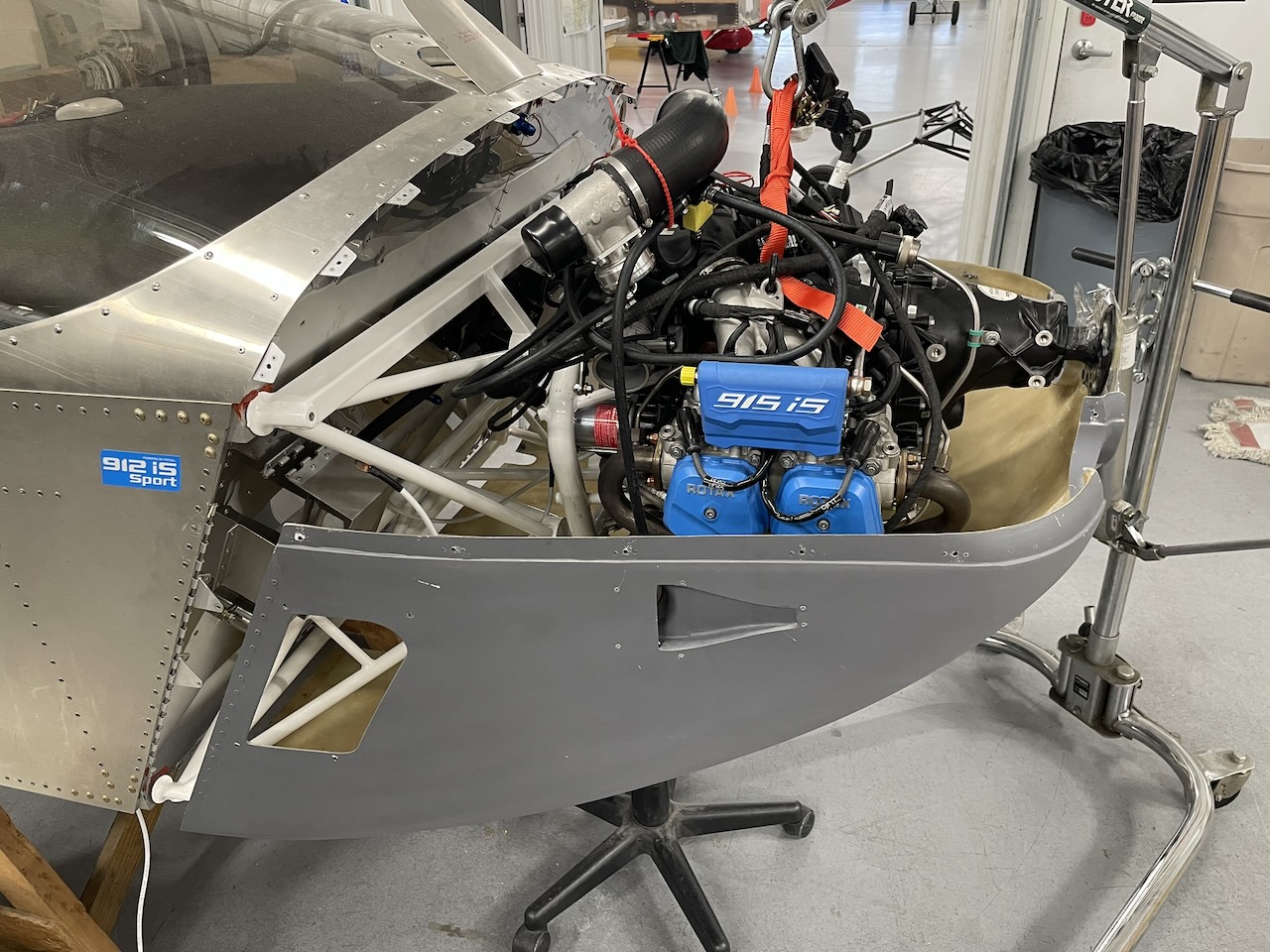

Preliminary fitting of the Rotax 915iS on Sonex production manager Cris Nash’s project aircraft in-preparation for the engine’s installation on the Tricycle Gear Sonex Highwing prototype. Sonex and Cooper Aircraft Corporation are collaborating on a dedicated cowling design for the installation to attractively cowl the engine and allowing maximum performance with minimum cooling drag.

Preliminary fitting of the Rotax 915iS on Sonex production manager Cris Nash’s project aircraft in-preparation for the engine’s installation on the Tricycle Gear Sonex Highwing prototype. Sonex and Cooper Aircraft Corporation are collaborating on a dedicated cowling design for the installation to attractively cowl the engine and allowing maximum performance with minimum cooling drag.

|

|

Sonex Highwing Kit Pricing:

While total kit price has not changed, we have redistributed some of the Sub-Kit items to better match the arrangement of our existing Sub-Kits, including separate sale of the engine mount and cowling. See our updated kit prices below and on the Sonex Web Store.

Complete Kits:

- Complete Airframe Kit: $39,000

- Quick Build Kit: $55,000

- Tri-Gear Option for Complete Airframe Kit or Quick Build Kit: $1,250

Sub-Kit Pricing:

- Tail Kit: $2,250

- Fuselage Kit: $14,450

- Fuselage Quick Build Upgrade: $10,000

- Wing Kit: $12,950

- Wing Quick Build option not available separate from fuselage purchase

- Gear & Controls Kit: $5,600

- Tri-Gear Option for Gear & Controls Kit: $1,250

- Engine Mount & Cowling (Std Gear): $3,750

- Engine Mount & Cowling (Tri-Gear): $3,350

- Kit Minus Tail Package: $36,750

The Bottom Line: What Will My Highwing Cost? Shipments Begin Year-End 2025!

|

Sonex Highwing Specifications & PerformanceSubject to change without notice

* Sonex Highwing features easily interchangeable wing tips for different span configurations. Sonex Highwing is designed to take advantage of the new FAA MOSAIC rules for Light Sport Aircraft! Specifications & Performance Subject to Change Without Notice. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||