Three steps forward, two steps back. The E-Flight Team continues to move ever closer to flight while turning setbacks into E-Flight system enhancements. The integrated system testing shown in the September update provided the team with a substantial amount of information and excitement. The full power motor runs turning a Jabiru 3300 propeller at 2800 RPM really show us that the airplane will be a lot of fun to fly. Initial climb rate should exceed that of the AeroVee powered airplane. With the good came some opportunities. Motor efficiency was slightly lower than the expected 92% which produced some additional heat rejection challenges, and battery cell integration has also slowed development.

E-Flight Motor and Motor Controller Enhancements:

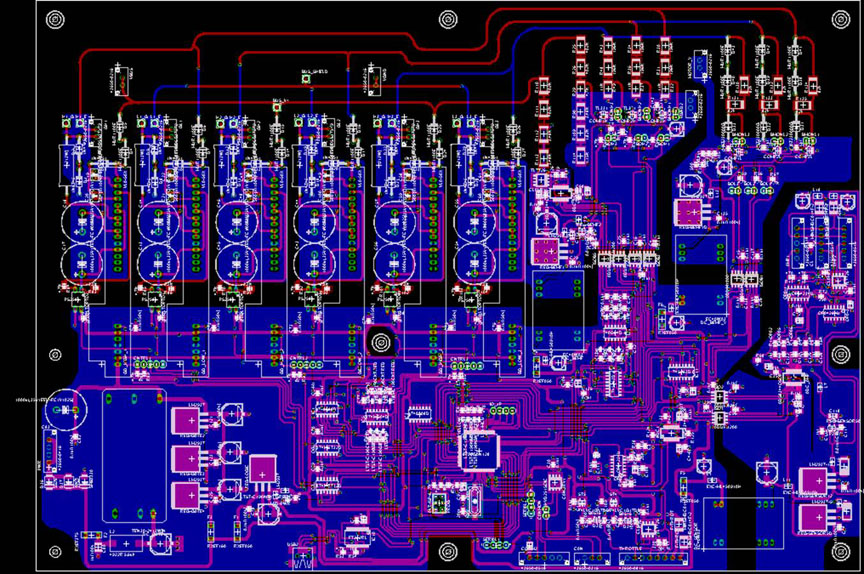

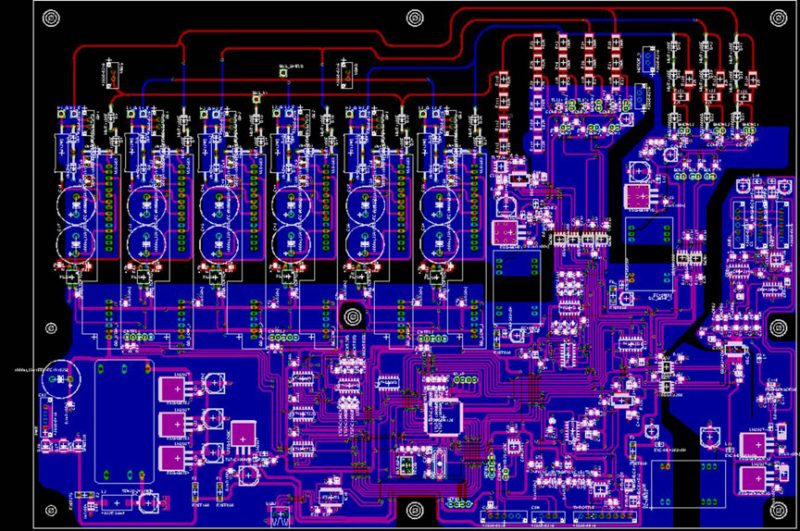

The need for efficiency and heat rejection enhancements displayed in the August testing is being addressed in 2 areas: the motor controller, and the motor hardware. The next generation motor controller (PCB shown at top,right) provides increased accuracy of the commutation at high RPM which increases the overall system efficiency (the low and mid RPM commutation has always been very good). Internal motor hardware changes are being implemented to tune the magnet rotor, minimizing inductive losses. The new hardware is currently in house and awaiting final assembly. The E-Flight Team elected to integrate these changes now while waiting for the battery upgrades.

E-Flight Battery Pack:

The largest setback has turned into the most exciting enhancement: Just after EAA AirVenture Oshkosh ’09, the E-Flight Team found that the lithium polymer battery cells which had been integrated into a full battery pack were not working out. Some events associated with our LiPo cells reminded us that these batteries require special handling and the E-Flight Team would like to caution anyone who is working with these cells that they carry potential hazards. From day one of the project, the LiPo cells initially sourced by the E-Flight Team were not intended as a production power pack assembly, but were intended as an initial power source for the E-Flight Electric Waiex prototype in lieu of the development of a more “plug & play” production pack.

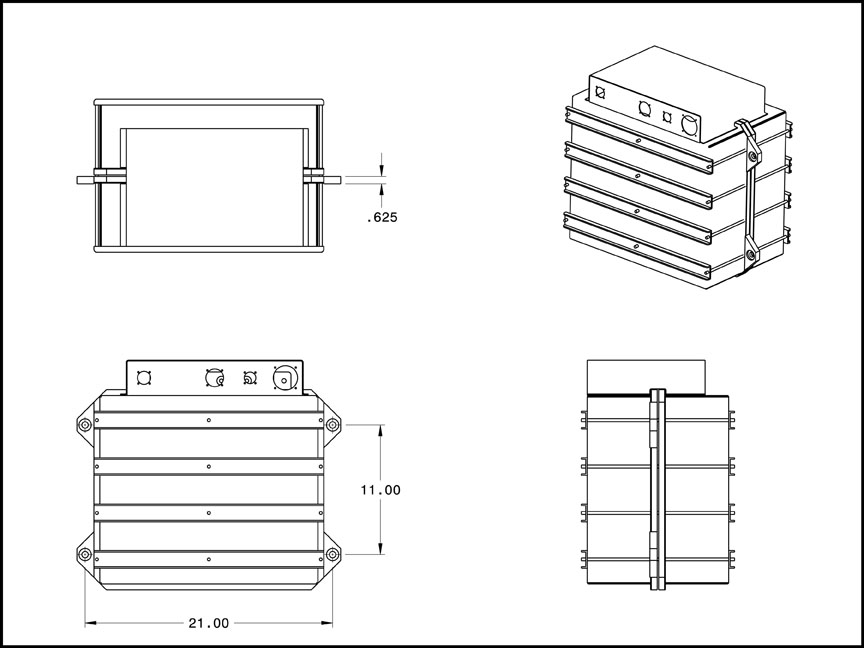

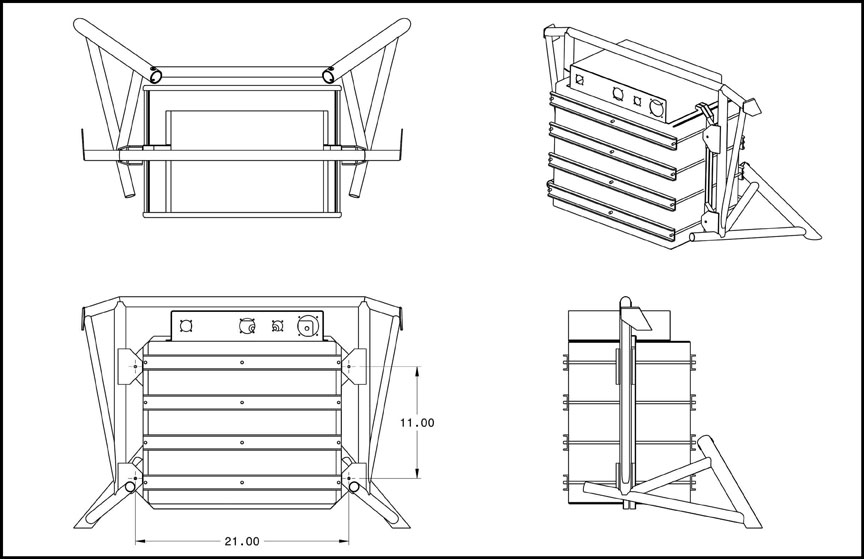

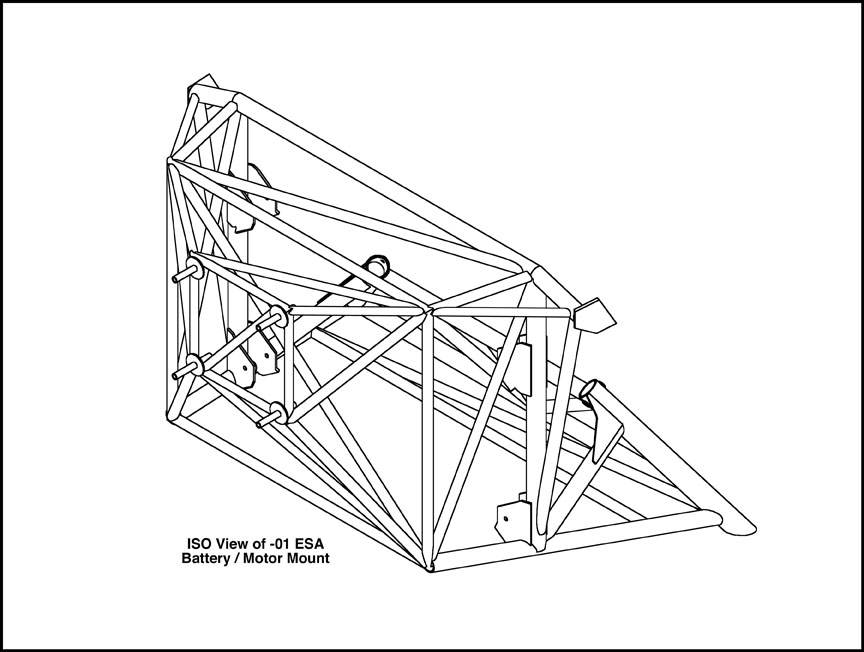

The E-Flight Team entered into negotiations with a leading aerospace firm’s battery power division for a new battery pack. The end result is a battery pack that incorporates qualified cell containment features and a fully developed battery management system integrating the architecture and safety features that the E-Flight Team has been developing. This package is expected to be delivered to the E-Flight team just after Christmas. Shown below one can see the format of this battery pack as well as the motor/battery mount which will be integrated into the Waiex-based E-Flight Electric prototype. The most exciting part of this development is that this new power pack is being produced with an advanced level of packaging and safety features that would allow it to be integrated into a consumer-level Electric Sport Aircraft product.

Our team remains extremely excited and motivated by this progress. We are confident that the development strides made in 2009 will result in an electric power system that is not only ready for flight demonstration in 2010, but also will be ready to become a commercial product shortly thereafter.